A specialized kind of 3D printer known as a food 3D printer is made specifically to produce edible objects and food items. Although it is specifically calibrated and set up to work with edible materials, it uses additive manufacturing principles that are similar to those used by other 3D printers.

Food 3D printers are available in a variety of designs and construction methods, including extrusion, powder, inkjet, stereolithography (SLA), and selective laser sintering (SLS). Based on a digital model or design, these printers employ various mechanisms to deposit or solidify food materials one layer at a time.

In this post we will discuss different types of food 3D printer you can use to get custom 3D printed parts, but first, lets look at the steps that are typically involved in using a food 3D printer:

Steps of 3D Printing Food

Step 1: Design or get a digital model

The desired food item must first exist as a digital model,just like with conventional 3D printing. This can be produced using CAD software, acquired from pre-existing digital models, or obtained through 3D scanning.

Step 2: Prepare food sources

The printing process’s raw materials are determined by the printer and the final product that is desired. Dough, chocolate, sugar, icing, pureed fruits, vegetables, and even liquid ingredients like sauces or batter are examples of common ingredients. To achieve the ideal consistency or texture for printing, these materials might need to be prepared or processed.

Step 3: Fill the printer up

A cartridge or other container that feeds into the printing mechanism is typically used to load the prepared edible material into the printer.

Step 4: Specify printing options

Users can modify a number of printing parameters, including layer thickness, print speed, temperature, and nozzle size, using the printer’s software to get the results they want.

Step 5: Print the object

The printing process starts after the digital model is loaded into the printer’s software. The printer builds up the final food item gradually by depositing or solidifying the edible material layer by layer as instructed by the model.

Post-processing and finishing

Some food items might need post-processing or additional steps for finishing touches after printing is finished. This can involve decorative elements, using glazes or coatings, or putting together various printed parts.

Food 3D printers have a number of benefits and uses. Prototyping with 3D printing is currently one of the best way to make products and model. 3D printers make it possible to create complex shapes, intricate designs, and precise customization that might be difficult to accomplish by hand. They allow for personalization and on-demand manufacturing, enabling the creation of distinctive food items for special occasions or dietary needs. Restaurants, bakeries, culinary institutes, and even individual homes use food 3D printers to explore new culinary possibilities and improve presentation and creativity in the food industry.

Different Types of Food 3D Printers and Their Capabilities

-

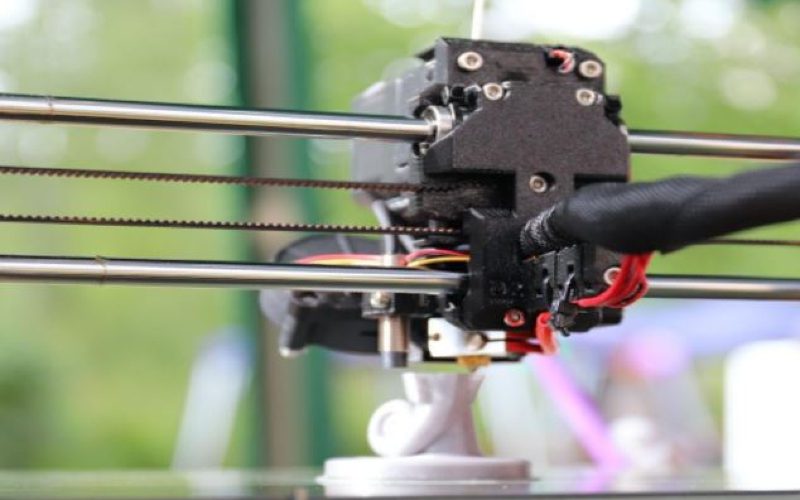

Printers based on extrusion

These 3D printers for food are the most prevalent ones. They operate similarly to conventional FDM (Fused Deposition Modeling) 3D printers by extruding food-based materials through a nozzle. Typically, the food ingredients are in the form of a semi-solid or paste, like dough, chocolate, or pureed fruit. Extrusion-based printers can produce a wide range of shapes and patterns, including complex textures.

-

Printers that use powder

The base material for these printers is a powder bed, and a liquid or other binding agent is used to selectively bind the powder together. Selective binding or inkjet printing are two terms used to describe this process. Sugar sculptures, confections, and intricate designs on cakes or pastries are frequently made using powder-based printers.

-

Using Inkjet Printers

The way food materials are sprayed onto a substrate in these printers’ precise patterns and layers is similar to how inkjet printers typically work. They can be used with liquid or semi-liquid food ingredients, including batter, sauces, and liquid chocolate. Inkjet printers are ideal for decorating desserts and adding intricate details because they excel at producing vivid and aesthetically pleasing designs.

-

Printers for stereolithography (SLA)

There are SLA printer modifications for printing food, even though resin-based 3D printing is where SLA printers are most frequently used. These printers work with a liquid photopolymer that turns solid under UV light. SLA printers can produce intricate and highly detailed food items, such as personalized candies or cake toppers, using food-grade resins or edible materials.

Depending on the particular printer and the materials used, different 3D printers can print different types of food. Typical abilities include the following:

- Creating complex and intricate designs that would be difficult to accomplish manually.

- Modifying the form, feel, and appearance of food products.

- Combining several flavors or ingredients into a single printed object.

- Enabling customization and on-demand manufacturing, like printing personal chocolates or customized cake decorations.

- Assisting in the production of food items that adhere to particular dietary restrictions, such as gluten- or allergen-free options.

- Enabling the investigation of novel culinary encounters and artistic displays.

It is worth noting that, food 3D printers must carefully consider food safety and hygiene standards, including the use of food-grade materials and upholding cleanliness throughout the printing process.

Conclusion

Food 3D printers are specialized machines that use the principles of additive manufacturing to produce edible items and food products. These include extrusion-based, powder-based, inkjet-based, SLA, and SLS printers, among other types and technologies. These printers make it possible to precisely customize items and create intricate designs and complex shapes that might be challenging to create by hand. They provide benefits like customization, on-demand production, and the investigation of new culinary opportunities. Restaurants, bakeries, and culinary schools use food 3D printers to increase creativity, presentation, and customization in the food industry while upholding standards for food safety and hygiene.